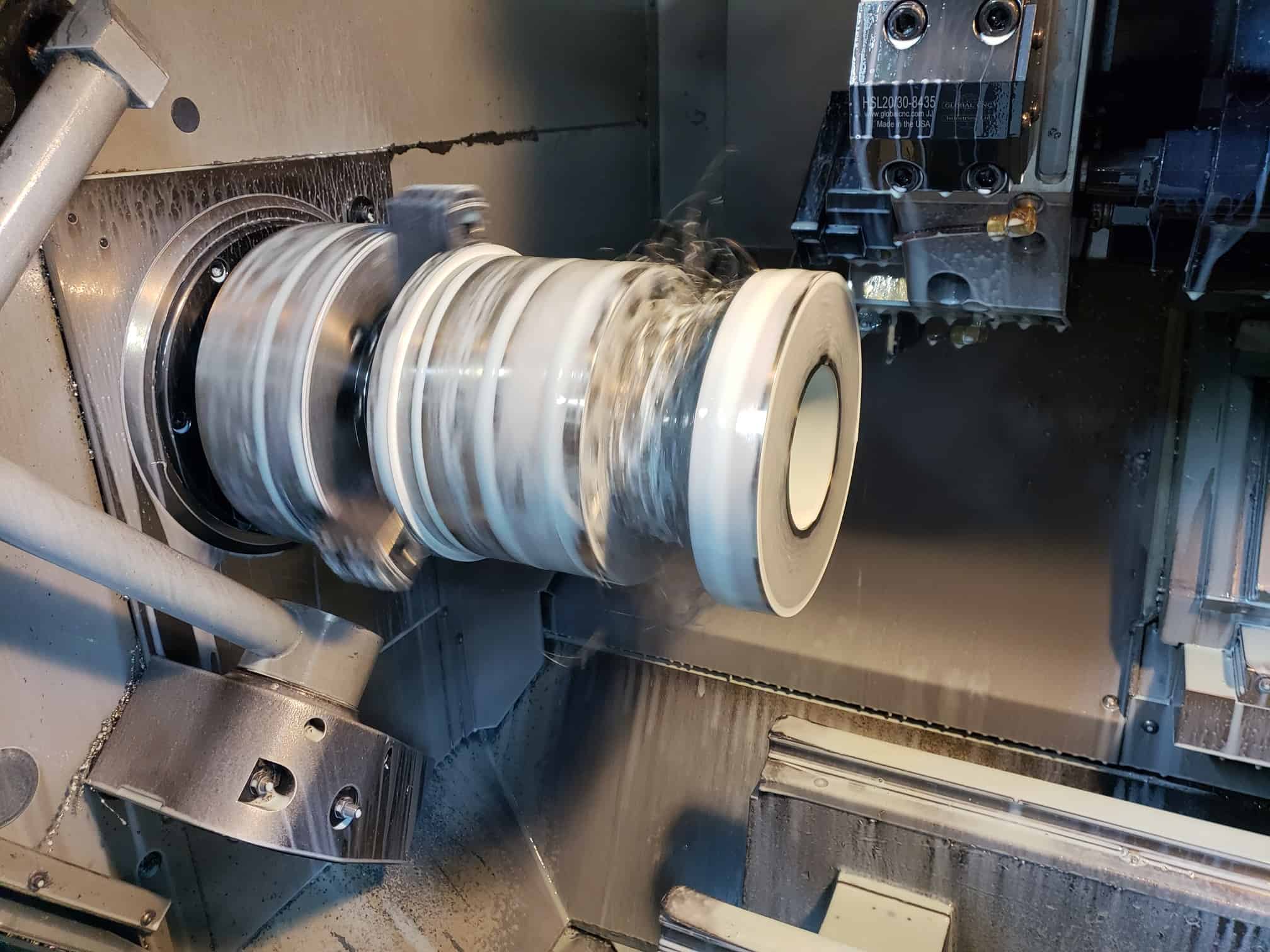

Don’t forget that FSI does reverse engineering! We recently reverse engineered 6 large sprockets for one of our customers. Check out our video of one of the sprockets on our Haas ST35 machine and the photos of the finished product!…

A Reliable Plant is a Safe and Cost-Effective Plant

. , – . . . – . , : ’ , , , , . .…

FSI is your go-to partner in finding a solution

, . . , . . – /” . #, , . – . ’ , ® ® (://./). . . ’ . – . –! …

Looking for a truly reliable pump? This is a must read!

FSI received a call from a customer who was experiencing pump issues with their newly installed pump. Since it had only been operational for two weeks, our initial assessment of the situation was that debris was accidentally left in the piping and was plugging up the pump. FSI went to work determining the cause of the problem. After removing the expansion joint from the pump suction, we found 8” flathead…

Ultimate Seal that Replaces the Use of External Flush

When a customer’s system was continually clogging due to the outside flush source, one of our distributors contacted FSI to review the application. Our distributor’s end-user was in need of a solution and wanted to get away from using their existing API Plan 32. An API Plan 32 delivers a clean flush fluid into the seal chamber from an external source.FSI recommended our newly designed and state-of-the-art 1040 EQ seal.…

Reverse Engineering Saves the Day!

A FSI distributor had an emergency seal repair and called FSI for a solution. The pump distributor’s end-user was experiencing down-time because when the pump was put into service, the pump locked up and wouldn’t turn freely. It was determined that the seal failed and the seal sleeve was found to be galled to the pump shaft. The pump was equipped with a Flowserve API Design seal. The end-user reached…

Minimizing Downtime While Maximizing Savings.

FSI partnered with one of our distributors, Anchor Seals Inc., to help solve a steel plant’s challenge. Read about how both companies worked together to get the job done while saving the customer time and money. Minimizing Downtime while Maximizing Savings. Anchor Seals introduced Fluid Sealing International (FSI) to a large steel company who was unsatisfied with what their vendor or supplier was telling them about a major pump repair.…

Ultimate Seal that Replaces the Use of External Flush

When a customer’s system was continually clogging due to the outside flush source, one of our distributors contacted FSI to review the application. Our distributor’s end-user was in need of a solution and wanted to get away from using their existing API Plan 32. An API Plan 32 delivers a clean flush fluid into the seal chamber from an external source. FSI recommended our newly designed and state-of-the-art 1040 EQ…

Case Study: Pump Bearing Housing – Reverse Engineering & Fabrication

Background: A crack or any deformation of the bearing housing of a pump can lead to excessive leaking. The bearing housing, as its name suggests, protects the internal pump bearings from damage and stores lubricant as needed. The pump bearings, although small in comparison, play a mighty role in supporting the full load of a pump at full rotation. We at FSI, recently received a call from our local sales…

FSI Can Solve Your Unique Pump Challenges

Tired of pump packing failures? FSI has your solution! Replace your pump packing with our 52SS two-piece split cartridge mechanical seal. Our 52SS split seal features two hydraulically balanced faces for optimum performance and installs outside the stuffing box, which saves the expense associated with replacement pump sleeves when converting from packing. Read how FSI engineered a solution for a Mississippi power plant that was facing challenges with their pumps.…