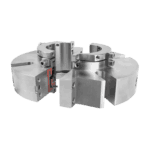

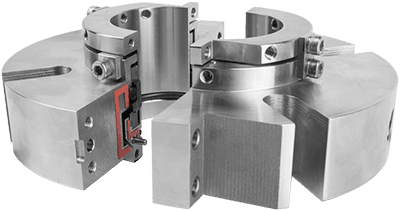

Most split seals require many hours to disassemble and reassemble rotary equipment, but Fluid Sealing International’s new Type 52SS Split Seal makes installation easy. Fully split, just attach both halves of this seal over the shaft, then mount it to equipment like any other cartridge seal. There’s no handling of individual parts, no shims, no special tools or glue are needed!

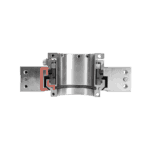

Our Type 52SS Split Seal features two hydraulically balanced faces for optimum performance and installs outside the stuffing box, which saves the expense associated with replacement sleeves when converting from packing. It also fits more equipment because there are no stuffing box restrictions. Only the seal’s two halves are handled, eliminating the need to touch sensitive lapped faces.

Since both faces are secured safely in cartridge halves, they can’t be cocked, chipped or scarred.

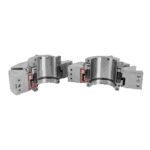

The unique stationary design of the Type 52SS Split Seal rotates less of a mass, which enables better tracking and prevents misalignment’s. It also uses centrifugal force to keep solids in suspension away from the faces while handling higher internal pressures and pump speeds. What’s more, the springs are isolated to prevent then from being clogged from solids.

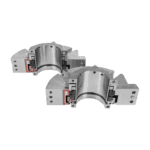

Fully assembled and pressure tested at FSI, the Type 52SS Split Seal has integrity sealed in before sent out to the field.