FSI has been driving innovative manufacturing solutions for over ten years in the Greater Pittsburgh area. From individual job shop manufacturing orders to OEM contract manufacturing projects, FSI consistently delivers products that meet or exceed customer requirements, production volumes and cost targets. Our pursuit of quality, consistency and continuous improvement has made FSI a growing leader in the industry.

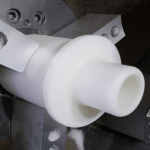

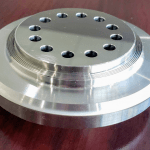

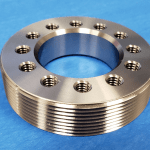

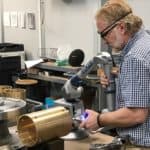

FSI’s core manufacturing competencies include everything from basic turning and milling, to complex automated four axis CNC machining.

FSI’s manufacturing facility is equipped with the latest technologies. With computer numerical control (CNC) machining and turning centers, we can provide customers with maximum flexibility, productivity and cost effectiveness. It is this combination of state-of-the-art equipment, manufacturing expertise and proven quality management that gives FSI – and our customers – a distinct advantage over the competition. If you are interested in FSI’s Manufacturing Capabilities or would like us to quote a project please contact us.

FSI's Core Manufacturing Capabilities

- Turning

- Milling

- Gasket Cutting

- Assembly

- Reverse Engineering

- Continuous Improvement

Auxillary Services:

- Coatings Anodize Cadmium Passivation CARC

- Fabrication Welding to D1.1

- 2D Cutting Plasma Water Jet Laser

FSI’S QUALITY SYSTEMS:

Our highly-recognized ISO 9001:2015 certification ensures that FSI’S quality management system and processes are controlled and will continuously improve. These controls ensure customer satisfaction, and demonstrate FSI’s commitment to continuously improve our customers’ satisfaction.

- Metrology equipment

- Geometric Dimensioning and Tolerancing (GD&T) expertise

MANUFACTURING:

FSI is a vertically- integrated engineering and manufacturing company that has been Driving Innovation in performance and reliability-enhancing components for over ten years. FSI offers a complete range of services, from collaboration on new product designs to custom contract manufacturing. Our principal products include Mechanical Seals and Custom and Standard gasket cutting.

From concept to completion, FSI takes a personal interest in your success. So, whatever your engineering and/or manufacturing needs –; manufacturing services such as turning, milling, CNC machining– you can count on FSI to meet or exceed your expectations.

Quality / Metrology Capabilities

In 2017, FSI made the decision to strengthen and reinforce our Quality program. Investing in a (coordinate measuring machine) and 3D imaging device to solve dimensional metrology problems. This decision allows us to not only perform in process Quality Control inspections but also reverse engineering of components that would take hours of hand measurements to validate and complete.

Technology from the portable CMM permits high-precision 3D measurement, imaging and comparison of parts and compound structures within production and quality assurance processes. The Portable CMM is used for inspecting components and assemblies, production planning, documenting small and large volume spaces or structures in 3D, and more. This measurement technology allows our company to maximize efficiencies and improve processes. This addition of technology sets FSI apart from other manufacturers in becoming a resource to our customers not just a supplier.

FSI as a company has company recognized that there is a need for collaborative partnerships with our customers. FSI works closely with our customers to provide onsite services to assist with Engineering and Quality. We strive to build and strengthen our relationships by better understanding the design intent and application of the end product. This helps drive product repeatability and throughput.

FSI is inspecting parts with ACD QC in Santa Anna, California using the FARO Arm.

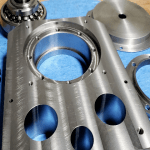

Gas Gun Project

Great job from all involved to keep on task!!!

Latest redesign / reverse engineered project completed at FSI. Customer request to take a cast part that did not have a existing TDP. Reverse Engineer the cast sample using our FARO arm with laser scanning capabilities we were able to provide the customer with (3) option to produce the final assembly. One week sooner than project deadline. Option 1 source a cast part – pricey and long lead times. Option 2 machine out of billet- long machine times due to multiple set ups and contour machining. Option 3 Weldment- breaking down the part into (4) piece part that could be welded together in complete assembly.

From cast part to weldment within the quoted time frame!