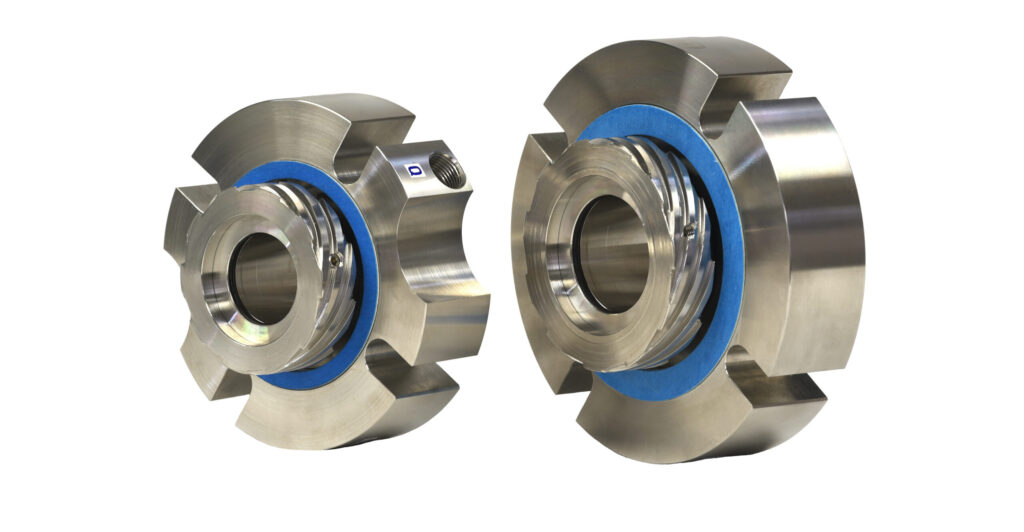

The state-of-the-art 1040 EQ is a single seal that performs like a double seal.

Features:

- Efficient Contra-Flow pumping ring, which keeps solids away from seal faces. No external flush needed.

- Largest diameter dynamic o-ring which is not subject to hang up due to design of externally lubricated system (XP Luber system).

- Multi-spring stationary design, eliminates detrimental misalignment between the pump housing and the shaft.

- Unique lug drive design which reduces stress on faces during upset conditions and heavy torque loads.

- Use of FKM lip seal which helps retain lubricant at seal faces and is a secondary lubricant to the seal.

- Chrome oxide coating on sleeve which assists secondary seal from premature failure.

- Monolithic face design eliminates all the problems associated with press fit/inserted faces.

Seal life is greatly increased by:

- Operating at very low differential pressures

- Seal faces are lubricated by a clean external fluid (XP Lube system)

- selected with properties that optimize performance

Operating Parameters:

ANSI-S

Sizes up to 5.000” Other sizes available per request

Temperature: t = 0-400°F

Higher temperature achievable with alternate FKM O-rings Sliding face material combination SC/Carbon

Pressure: p1 = 300 PSI (21 Bar)

Speed = up to 5000 FPM

Sliding face material combination SC/SC or SC/TC

Pressure p1 = 175 PSG (12 bar)

Speed = 33 ft/s (10m/s)

Permissible axial movement: +- 0.040”

D1>3.000” +- 0.060”

Materials of Construction:

- Metal Components: 316 SS Standard

- Seal Face Materials: Carbon, Silicon Carbide, Tungsten Carbide

- Elastomers: Fluoroelastomer, Perfluoroelastomer, Aflas, EPR/EPDM as standard o-ring materials. All other commercially available elastomers as specified.

Pumping screw requirements:

1750 RPM:

- Maximum suction pressure: 8 psig

- With plan 13 maximum suction pressure: 10 psig

3600 RPM:

- Maximum suction pressure: 15 psig

- With plan 13 maximum suction pressure: 30 psig

Below 1750 RPM – Consult engineering

Referencing now the above figures plus figures 4 and 5:

*Patent pending