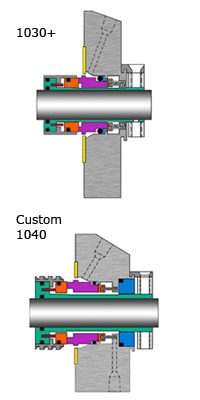

The Series 1000 seals are available in standard sizes for all ANSI / DIN process pumps. In addition, the 1030+ and the 1040+ are designed to accommodates all big bore, taper bore, and oversized stuffing box arrangements.

Other offerings within the Series 1000 family include the following products in standard materials:

- Type 1010 – Single cartridge elastomer bellows with single coil spring and one flush port.

- Type 1020 – Single cartridge flexible stator with press fit faces and plain gland.

- Type 1020M – Single cartridge flexible stator with monolithic faces and one flush port.

Because of our versatility in manufacturing, the FSI Series 1000 cartridge seal line is ideally suited for a variety of equipment types…..these would include:

- Horizontal split case pumps

- Slurry pumps

- End suction centrifugal pumps

- Vacuum pumps

- Rotary & Screw pumps

- Vertical pumps

- Progressive cavity pumps

- Specialty equipment

The use of modular parts for seal face configurations provides for maximum interchangeability. At the same time, the Series 1000 seals can incorporate custom manufactured glands and sleeves to accommondate all types of equipment. This is done without sacrificing seal performance, and in nearly all instances, without requiring equipment modification to accept the seal.

CUSTOM DESIGNS ARE ACTUALLY STANDARD PROCEDURE AT FSI – CUSTOMER DRIVEN DESIGNS!

OPERATING PARAMETERS:

OPERATING PARAMETERS:

- Temperatures: 0°F to 600°F* ( -20 C to 300 C)

- Pressures: Up to 600 psi* (40 Bar)

- Shaft Speeds: Up to 3600 RPM*

MATERIALS OF CONSTRUCTION:

- Metal Components: 316 SS Standard

- Seal Face Materials: Carbon, Silicon Carbide, Tungsten Carbide

- Elastomers: Fluoroelastomer, Perfluoroelastomer, Aflas, EPR/EPDM as standard o-ring materials. All other commercially available elastomers as specified.

- Sizes: Up to 6.00