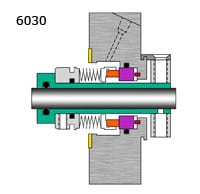

The 6030 & 6040 mechanical seal line is a single cartridge rotating metal bellows seal designed for general service in refinery, petrochemical, and chemical industries.

The 6030 & 6040 mechanical seal line is a single cartridge rotating metal bellows seal designed for general service in refinery, petrochemical, and chemical industries.

FEATURES:

- Inherently and hydraulically balanced

- Centralized face loading ensures even face loading (flatness) throughout all temperature and pressure ranges

- Tangential porting to maximize flush effectiveness

- All o-rings are static; no dynamic o-rings

- Rotating bellows design are self cleaning, through rotational expulsion of particulates

- The 6040 is provided with quench and drain ports as standard. Options include restriction bushing, lip seal or die formed graphite ring containment system.

- Temperatures: 0°F to 750°F* (-20 C to 380 C)

- Pressures: Up to 300 psi* (20 Bar)

- Shaft Speeds: Up to 3600 RPM*

MATERIALS OF CONSTRUCTION:

- Metal Components: AM350 SS, nconel 718 as Standard

- Seal Face Materials: Carbon, Silicon Carbide, Tungsten Carbide

- Elastomers: Fluoroelastomer, Perfluoroelastomer, Aflas, EPR/EPDM as standard o-ring materials. All other commercially available elastomers as specified. Type 6090 utilizes Graphoil secondary seals for high temperature applications.

- Sizes: Up to 5.00