Entreprise Globexseal Inc. in partnership with Fluid Sealing International, started back in July 2016 a multiple Seals conversion project on Slurry pumps applications (Slurry from 29% to 60%). The main objective was to reduce the treated water consumption at the mill level and also reduce cost of ownership and increase reliability.

Seals:

Phase one included a total of 12 Warman pumps AH Model of various size from 4×3, 6×4, 6×8, 10×8 & 400M. All the pumps were converted from packing to (FSI) Type 2080 Double mechanical seal, MS2080NxxMMSS6XII.

Conversion KIT:

In order to convert the pumps from packing, “Conversion Kit” was supplied for each pump. The conversion kit included a Back Plate (316SS) and a new sleeve (316 SS). (Only required the first time)

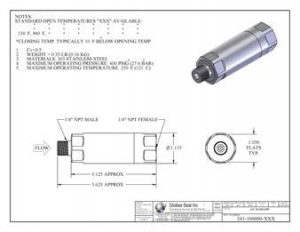

Flushing Plan:

Seals were installed with a dead end flush to a Thermostatic valve, 130 deg F open /140 deg F. close. We also included a ball valve to clean the line weekly, since the flush water contain 1-2% solid.

We were able to reduce the water consumption from 3.6-7.8 M3hr with packing to practically zero with mechanical seals.

Not only the reduction of treated water consumption objectives were obtained, Cost saving were significant and reliability of the equipment’s increased. Another great success all the way!

For more details on these applications, feel free to contact us.